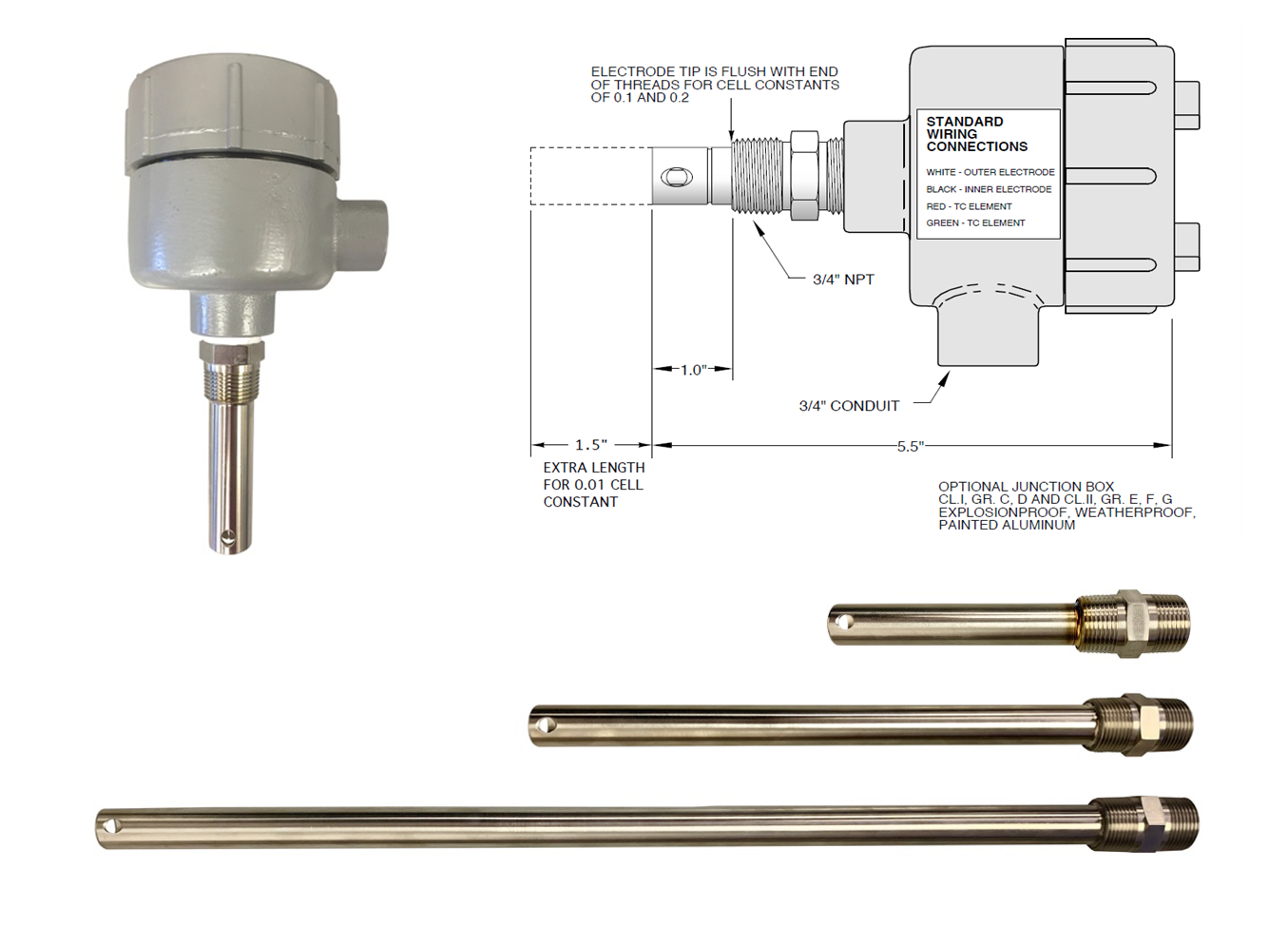

High Temperature Conductivity Sensor

- Product Details

- Specifications

- Insertion Depths

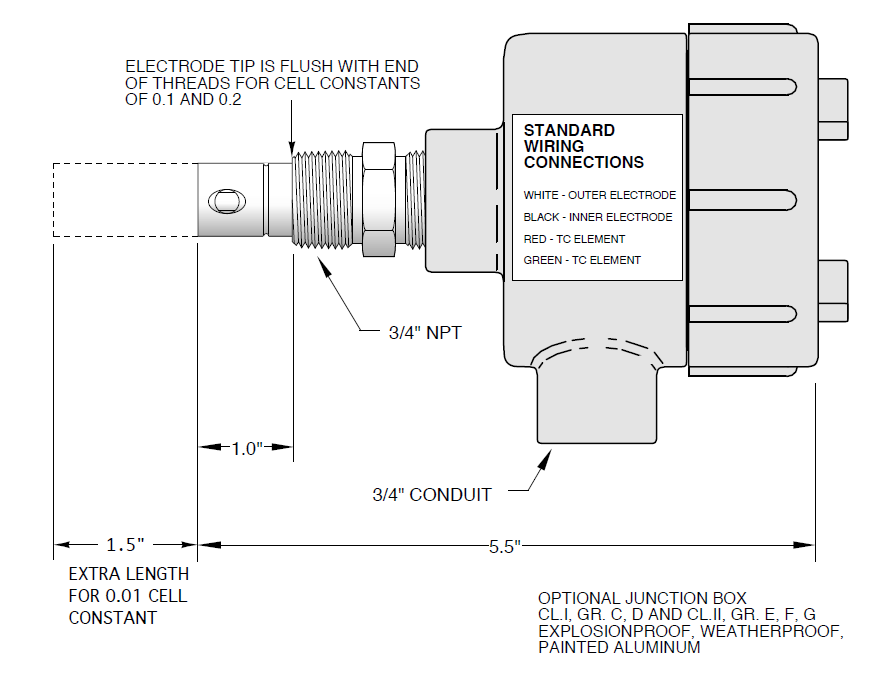

- Sketch

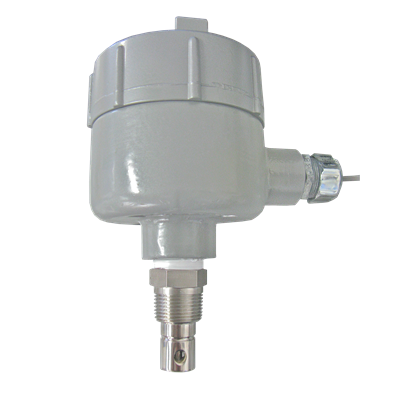

CHEMTROL® High-temp conductivity sensor

Designed for high pressure, high temperature conductivity measurements, and is an ideal choice for boiler control applications.

Blowdown control, condensate monitoring, leak detection on heat exchangers, and steam purity measurements are just a few of the many applications in which this rugged and reliable sensor can be used.

-

Measure conductivity directly in process temperature up to 205ºC

-

O-ring seals used on all versions for high on-stream reliability

-

Boiler condensate and blowdown control without coolers

Specifications

Wetted materials of construction are 316 stainless steel, PEEK, and EPDM o-rings. All possible leak paths through the sensor are double sealed with o-rings for maximum on-stream reliability. Hot water is a severe environment for any elastomer, and the front seals bear the brunt of chemical attack, allowing the back seals to remain relatively unaffected. The result is that sensor life is more than double what can be expected of single sealed, or epoxy sealed units.

Max. Pressure/Temp. Ratings:

- Standard Sensor – 100 PSIG at 150ºC

- High Temp. Sensor – 250 PSIG at 205ºC

- Either Sensor – 500 PSIG at 100ºC

Wetted Materials:

- Electrodes – 316 Stainless Steel

- Insulator – PEEK

- O-Rings – Parker EPDM, Steam Service. FDA APPROVED

Connections

- Process – 3/4″ MNPT

- Electrical – 3/4′ FNPT conduit hub; terminal strip to accept stripped leads, 14-24 ga.

- Optional junction box – 3/4″ FNPT – waterproof enclosure designed for high temperature sensor environment with 3/4″ conduit outlet