Blade-Style Flow Switch

- Product Details

- Specifications

- Typical Users

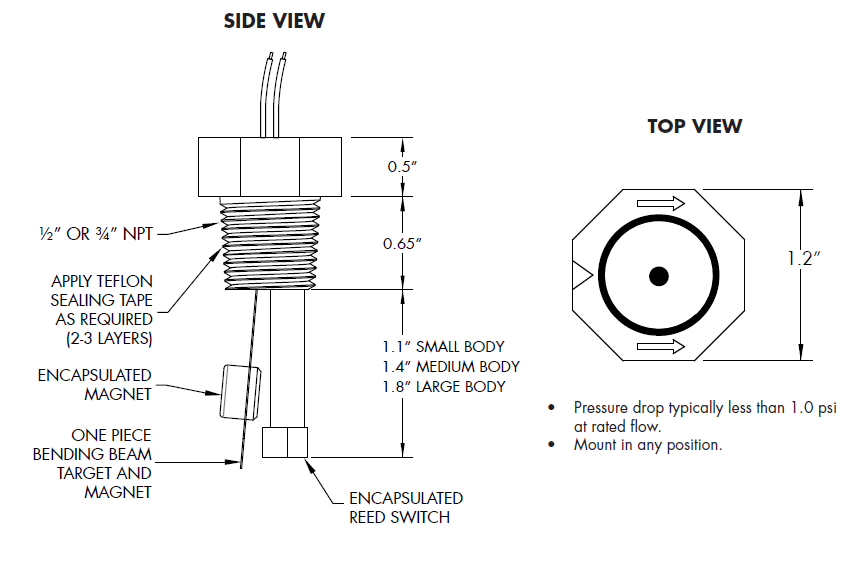

- Sketch

Blade Style Flow Switch

Since the mid 1980’s these blade-style flow switches has been used by some of the largest companies in the fluid control industries as well as Pool & Spa. It has several factory adjustable parameters that provide the flexibility to meet the requirements of almost any application.

The blade-style switch verifies fluid flow, typically in conjunction with another device. For example in a chiller it prevents the system from freezing, and in most of swimming pool salt chlorine generators it has been used to verify sufficient flow before the generator is energized. In a spa or hot tub it ensures sufficient flow to prevent the water heater from a meltdown, and at home it turns on the water disinfection system when someone is getting a glass of water.

Typical Working Fluids

For use in a broad spectrum of industrial fluids, such as:

- Cooling Tower Water

- Water (saltwater, pure, tap, etc.)

- Glycol Solutions Lubricating Oils

- Mild Acids Gasoline

- Plating Solutions JP-4

Standard Features

– Max. flow may be five times normal flow.

– Positive stop eliminates fatigue effects of turbulence, vibration and flow surge on flow detecting element.

– Very low pressure drop – typically less than 1.0 psig at normal flow rate.

– Small size and low profile provides easy mounting in crowded installations.

– Power the driving coil of small ice cube relays as well as some 30A power relays.

– Switches 5VDC to 240VAC.

– Switch employs magnetic coupling.

– Can be used in ¾ inch to 6 inch pipe

| Flow Range | 0.7–590 GPM (2.6–2,233 L/m) |

| Working Temp | 200˚F (93˚C) Maximum |

| Working Pressure | 250 psi (1.724 kPa) |

| Process Connection | 1/2″ NPT, 3/4″ NPT |

| Electrical (Reed) Switch | SPNO (single pole normally open) 0.5A* |

| Enclosure | NEMA 4X / IP 66 |

In Chemical Processing:

- Fluid Blending Systems

- Liquid Transfer

- Heat Transfer Fluids

- Monitor Filter Clogging

- Liquid Scrubbers

- Starting back-up pumps

- Monitoring pump output, valve position, systems flow status

In Pool and Spa:

- Protect water heater in Spa

- Protect water heater in Pools

- Turn on Salt Chlorinator

- Turn on UV System

- Turn on Ozone System

Monitoring flow of coolant supplied to:

- Brakes and Clutches

- Emergency Wash-Down Showers

- Computer Systems

- Marine and Stationary Engines

- Diodes, SCRs, Triacs, etc.

- RF and Radar Transmitters

- Electromagnets

- Spot welders

- Fire Sprinkler Flow Alarms

- Transformers

- Lasers

- Vacuum Systems

In Water Treatment:

- Irrigation Systems

- Salt and Fresh Water Systems

- Chemical Feed Pump Control