Feed Programs Selection

Chemical feed programs are a key strategy to minimize the risks associated with poor water quality in cooling towers. They are critical for ensuring microorganisms, including Legionella, are eliminated, as well as minimizing scale formation and corrosion. Over the last 40+ years we have developed programs, in conjunction with feedback from our customers, for a variety of chemical feed programs.

Chemical Feed Programs – Operation

The ADDITIVES menu is used to program the addition chemicals that cannot be controlled through sensor input, such as: corrosion and scale inhibitors, non-oxidizing biocides, flocculants, dispersants, etc. The additive menus can be customized by selecting names in the Configuration/Additives Sub-menu from a pre-defined list. Each ADDITIVE has a sub-menu to set the control mode, alarms, display of individual feed events, cumulative run time and Scheduled Booster.

Control Mode selection

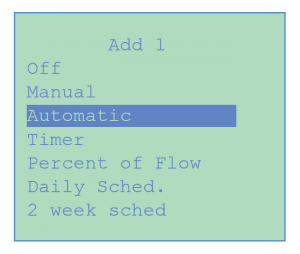

The first screen of the Control Sub-menu is used to select the control type:

- OFF (X),

- Manual (M)

- Automatic (A)

- Cycle Timer (T)

- Percent of Flow (F)

- Daily Schedule (S)

- 2-Week Schedule (B)

If the operator selects OFF, the controller turns off the feed control outlet immediately and returns to the previous menu. If the operator selects Manual, the controller turns on the feed control outlet immediately and returns to the previous menu.

CAUTION: When set to Manual, the outlet remains activated until reset to off. If the run time exceeds the Time Limit set by the operator in the specified sub-menu, the outlet will be turned off to prevent overfeeding.

Time Limit: Designed to alert the operator in case of a malfunction of the chemical feeder. The maximum amount of time in minutes that is allowed for continuous feeding of the additive.

Run Time: The RUN TIME displays the time in minutes for current activation and cumulative run time since last reset to zero. To reset the cumulative run time, enter zero in the last column. To reset only the current run time, turn the control mode off and back on.

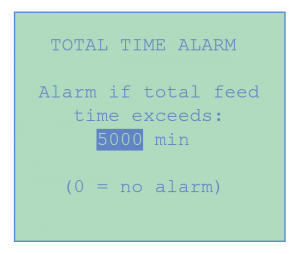

After the cumulative run time is reset, the TOTAL TIME ALARM sub-menu is displayed to set the Total Time Alarm option.

It can be used to simulate a low chemical level alarm by entering the number of minutes needed to empty the chemical container: Container volume divided by feeder rate (e.g. 6000 min / 60 = 100 hours / feeder rate of 1 LPH = 100 litre container).

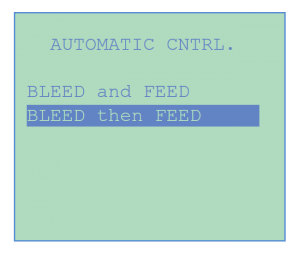

With the AUTOMATIC control mode, the operator can select either Bleed-and-Feed or Bleed-then-Feed (post-bleed as a percent of bleed) control.

Bleed and Feed: In the Bleed-and-Feed control mode, the controller activates the control outlet at the same time that water is bled. In the Bleed and Feed Sub-menu the operator can specify the percentage of bleed time and the maximum time in minutes allowed for feeding. If additional feeding is required, the operator can set a complementary feeding on a daily schedule program.

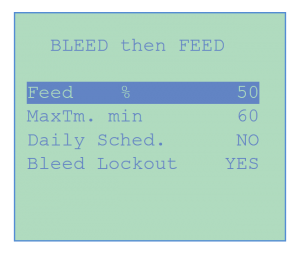

Bleed then Feed: To prevent the loss of additives with bleed water, Bleed-then-Feed can be used. In the Bleed-then-Feed control mode, the controller activates the feed only after bleed is completed as a percentage of bleed time.

The Bleed Lockout function prevents bleed during and after feed and specifies pre-bleed and/or pre-pH function.

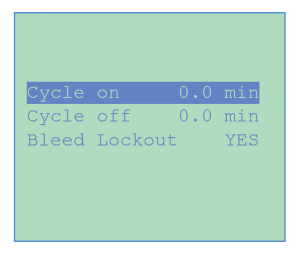

In this mode, the controller activates the control outlet according to fixed ON and OFF cycles. Each cycle is adjustable in 0.1 minutes increments. Selection of the Bleed lockout function, displayed on line 3, is used when it is desirable to lock chemical feed during bleed and lock bleed during and after feed.

The Bleed Lockout function prevents bleed during and after feed and specifies pre-bleed and/or pre-pH function.

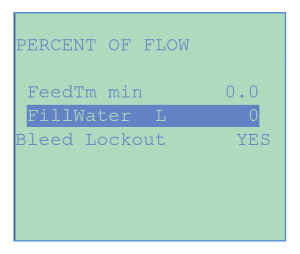

In this mode, the controller activates the control outlet for a length of time that is proportional to the volume of fill water as monitored by the fill flowmeter (gallons or liters). The % Flow Sub-menu displays the amount of time in minute for the selected volume of water.

The Bleed Lockout function prevents bleed during and after feed and specifies pre-bleed and/or pre-pH function.

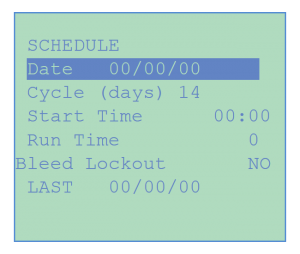

In the Daily Schedule Control mode, the controller activates the control outlet for selected daily intervals – regardless of sensor input. Selection of the Daily Schedule control mode leads to the Daily Schedule Sub-menu.

The operator selects the date of the first treatment (“Next Date”) and the cycle in days for repeat treatments. The operator also sets the start time and duration (in minutes) of the treatment. “Last Date” shows date of last treatment.

The Bleed Lockout function prevents bleed during and after feed and specifies pre-bleed and/or pre-pH function.

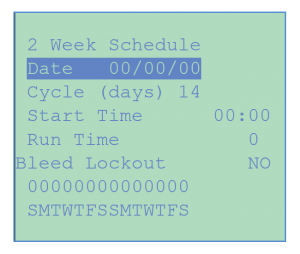

Much like the Daily Schedule Menu, the controller activated the control outlet for selected times. However, with this option, you can choose the days of the week that you want to feed.

An important programming difference is that in this function, the Date field must be programmed to the SUNDAY PRIOR TO THE FIRST FEED DATE. With this option, you select the feed days by highlighting the days line, change the “0” to a “1”.

The Bleed Lockout function prevents bleed during and after feed and specifies pre-bleed and/or pre-pH function.

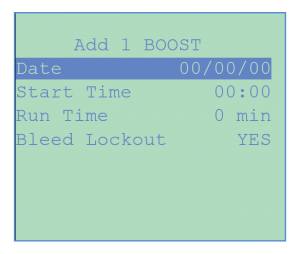

The Booster (Single Shot) function is used to schedule a delayed one-time feed event (i.e. feeding the biocide at 1:00 AM for an hour). It is independent of the other control modes.

The Booster Sub-menu allows selection of the date, start time and duration of the feed event.

The Bleed lockout function prevents bleed during and after feed and specifies pre-bleed and/or pre-pH function.

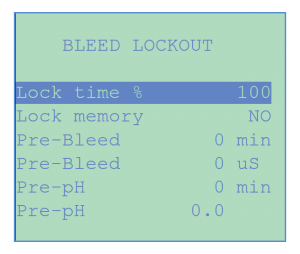

The Bleed Lockout sub-menu is used to prevent bleed during – or immediately after – feeding of chemicals and to specify pre-bleed and/or pre-pH feed operations.

- Line 1 displays the bleed lockout time in percentage of feed time. A value superior to 100% prevents bleed during and after feed.

- Line 2 displays the lock memory option to accumulate feed lockout time until bleed is completed.

- Line 3 and 4 display the pre-bleed option to reduce the risk of deposits due to increasing conductivity or TDS level during a lockout period. The pre-bleed can be specified for a length of time and/or until a conductivity level is reached.

- The Pre-pH option is used to adjust the pH level before additive feed. The pH feed can be set for a length of time (line 5) and/or until a pH level is reached (line 6). The controller maintains the pH level during the entire feed cycle.