Run-time Precaution Limit

Run-time Precaution Limit (Overfeed Safety)

The Time Limit settings are designed to automatically disable the feeders or other equipment in the event of equipment failure or operator error such as:

- Sensor or electronics failure,

- Chemical feeder malfunction,

- Improper valving of the re-circulation system,

- Manual override of automatic control by untrained or unauthorised personnel,

- Depletion of chemical supply.

In normal operation, the chemical feeders are activated only for a short period of time – that is until the chemical level in the water has returned to the proper value. As soon as the chemical feeder is activated, the safety timer is turned on.

Normally, feeding stops before the time limit is reached. The timer then resets to zero and waits for the next activation cycle. However, if feeding continues over the preset time, the timer immediately stops the feeder and activates the overfeed alarm.

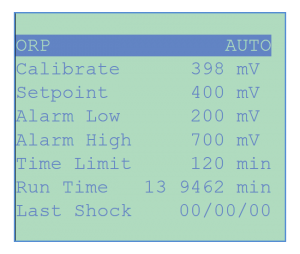

Timer Settings

To select the proper setting for each safety timer, the operator must take into consideration the size of the system and the feed rate of the chemical feeder. In case of doubt, make sure to consult a qualified CHEMTROL® representative.

NOTE 1: The chemical feeders should be properly sized for the installation so that they do not have to feed continuously for more than 3 hours – even during peak usage periods.

NOTE 2: Once tripped, the safety timer has to be reset manually by the operator after investigation and correction of the malfunction.

The TIME LIMIT sets the maximum amount of time in minutes that is allowed for continuous feeding of the chemical to correct a high or low level reading. This acts as a safety feature to prevent overfeeding in case of a malfunction of the chemical feeder or as an alarm if the feed tank runs empty. The standard (default) value is set as 15 minutes but it can be changed at any time by the operator.

NOTE, Time Limits for each outlet should be set for the length of time that can be safely tolerated for chemical overfeeding – in case of equipment malfunction or operator error. This time varies with each installation, based on the size of the installation (liters of water) and the feed rate of the chemical feeders.