Scheduled Chemical Booster

Shock Treatment

Shock Treatment refers also to chemical booster treatment with an elevated level of oxidizer which should be performed from time to time to prevent the accumulation of noxious chemicals (chloramines) or biological forms (algae, etc.).

Even when maintaining the proper chlorine residual level with Chemical Automation, it is recommended to shock or

super-chlorinate the water periodically for the following reasons:

- To prevent algae growth resulting from genetic adaptation of algae species to chlorine, i.e. becoming chlorine resistant.

- If the chlorine level is allowed to fall below the normal level, even for a short period of time (due to exhaustion of chemicals or technical malfunction), there can be formation of chloramines, which can be destroyed only by break-point super-chlorination.

Treatment Selection

– The Shock Treatment program is used to raise the level of oxidizer or sanitizer in the water in order to destroy harmful elements – such as chloramines, germs and algae – that develop immunity to normal chemical levels.

– The Booster program is used to to schedule a delayed one-time feed event, such as during nighttime or on weekends. It is independent of other control modes.

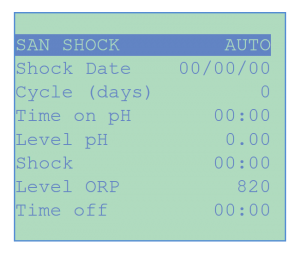

Shock treatment program

The Shock Treatment Sub-menu allows the operator to set the program to OFF, ON or AUTO. When set to ON, the Shock Treatment program starts immediately. When set to Automatic, the operator selects the date of the first treatment and the cycle in weeks for repeat treatments. He also sets the time to start and time to stop as well as the level of shock treatment to reach, in mV for Shock Treatment or in ppm or mg/l for Super-chlorination.

Chemical injection stops when either the set level is reached or the end time is reached.

Booster treatment program

The Booster program is used to schedule a delayed one-time feed event, such as during nighttime or on weekends

(i.e., feeding the oxidizing biocide at 1:00 AM for an hour). It is independent of other control modes.

The Booster Submenu allows selection of the date, start time, and duration of the feed event.

WARNING:

If there is a concentration of chloramines of 0.2 PPM (mg/l) or more, a superchlorination level of 10 times the combined

chlorine level is required. The shock treatment program can be set up either through the ORP Menu or the SANITIZER Menu, depending on the choice of chemicals. The weekly cycle, date and time should be selected based on the particular requirements and utilization schedule of the facility.

Precautions

- During super-chlorination, the Time Limit safety is bypassed.

- A SHOCK treatment warning is displayed on the Display Screen when activated.

- The out-of-range alarms stay on as long as the oxidizer or sanitizer levels are above the high limits.