Conductivity Control

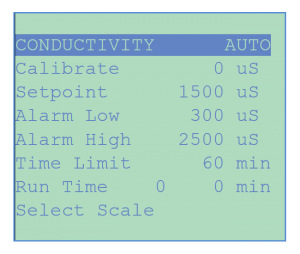

Conductivity Menu

The Conductivity Menu is used to monitor the concentration of dissolved solids in the water. These data can be displayed either in conductivity units (microsiemens/cm) or in ppm of Total Dissolved Solids (TDS), using an operator-selectable conversion factor.

The CHEMTROL® PC3000, PC5000, PC6000 and PC7000 Programmable Controllers continuously monitor the level of dissolved solids in the water (TDS) with a conductivity sensor.

Readings are displayed in conductivity units, microsiemens/cm (µS), using the CONDUCTIVITY MENU or in parts per million (ppm) of Total Dissolved Solids (TDS) using the TDS MENU, with an operator-selectable TDS conversion factor. Menus set automatic replacement of water (dumping or bleeding) when TDS values become too high, referring to a Conductivity or a TDS set-point to activate a dump valve. Back-filling of water is done simultaneously with a level control activated valve.

The Conductivity Menu allows monitoring and control of the conductivity or TDS levels, with selection of:

The Conductivity Menu allows monitoring and control of the conductivity or TDS levels, with selection of:

- Dump mode:

– Off

– Manual Dump

– Auto Feed in ON/OFF or Proportional modes with adjustable deadband and bandwidth

– Timer with adjustable ON and OFF cycles - Sensor calibration in µs (microsiemens) (1, 2 or 3 points)

- Control Setpoint in µs (microsiemens)

- Low Alarm in µs (microsiemens)

- High alarm in µs (microsiemens)

- Time Limit with adjustable overfeed safety shutoff

- Chemical Additions with daily programs for up to three different additives

- Scale Selection for TDS factor

For Cooling Tower applications, up to three different types of chemical additives, such as inhibitors and biocides, can be independently programmed for automatic addition as a function of time, bleed activation, pH control activation or cumulative flow rate.