Pump Control

Pump Menu

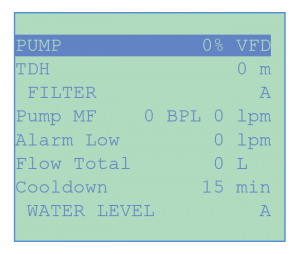

The PUMP MENU is used to run the pump on manual for 24-hour a day continuous operation or on automatic with a seven-day cycle program.

The flow and pressure sensor readings can be used for automatic start-up of the Filter Backwash Cycle. The “Fireman” protection feature allows for cooldown of the heater before pump shutdown.

The menu selections include:

The menu selections include:

- Run Mode

– Manual for continuous 24-hour operation

– Automatic with seven-day scheduling - Influent Pressure reading in psi or kg/cm2 from pressure sensor with adjustable calibration

- Effluent Pressure reading in psi or kg/cm2 from pressure sensor with adjustable calibration

- Flow Rate reading in gpm or m3/s or from flow sensor with adjustable calibration

- Total Flow in ga or m3 with cumulative reading and reset

- Heater Delay for “Fireman” protection to allow for cooldown of the heater before water recirculation is stopped.

Pump Control

The CHEMTROL® PC6000 and PC7000 Integrated Controllers feature automated control of the main recirculation pump and automated backwash of single or multiple filters using different programs based on fixed schedules or on pressure differential criteria.

The same program is also available on the CHEMTROL® PC4000 Filter Controller.

Pump Programming

The PUMP MENU is used to set operation of the main recirculation pump to manual for continuous 24-hour operation or to automatic with a seven-day schedule.

Protection of the heater is assured with the adjustable “Fireman” Heater Delay to allow for cooldown of the heater before water recirculation is stopped.

The pump operation is monitored with a flow switch and with pressure switches in and out of the filter. Both flow rate and influent pressure are displayed on the monitoring screen.

High and low pressure limits can be set to interrupt the pump operation in case of emergency, such as malfunction of the valves or filter.

Backwashing of the filter is programmed with the FILTER CONTROL.