Latest

-

Sustainability: Cooling Towers

Sustainability and Cost Benefits of CHEMTROL® Controllers: Cooling Towers

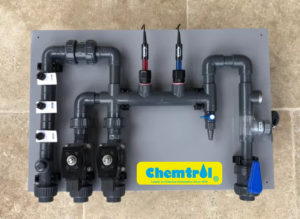

Installation of CHEMTROL® programmable controllers for cooling towers

Cooling towers by their very nature consume water as they perform their function of evaporative cooling. This is primarily via bleed, evaporation, makeup and drift losses.

For large facilities this can be one of the highest water-use areas, and account for up to 50% of the site’s water use.

With this in mind we want to highlight how our range of smart automated water treatment systems can improve efficiency and help your facility be more sustainable and cost efficient to operate.

Sustainability benefits for cooling towers

The sustainability and efficiency benefits of using our controllers – in conjunction with an experienced water treatment service provider – include:

Water Savings

Our state of the art chemical dosing system enables operators to run higher cycles of concentration without having a negative impact on the cooling tower system. Running higher cycles of concentration will save on bleed and make-up water.Energy Savings

Scale build up within a cooling tower system will affect the heat transfer capacity of the cooling towers/chillers. Controlling scale formation and dissolving any already formed substrate will improve the heat transfer capacity of the system, and therefore, reduce operating costs. A properly designed and sized chemical dosing and filtration system will improve system performance by allowing accurate chemical dosing to achieve desired parameters and removing suspended solids from the recirculating water. This helps keep cooling systems operating at maximum design efficiency.Longer Equipment Life

Maintaining clean tower water significantly reduces the potential for corrosion throughout the cooling system. Keeping the system surfaces clean allows the corrosion inhibitors to more effectively form the desired protective film on metal surfaces. State of the art chemical dosing and filtration systems also help prevent under-deposit corrosion.Improved Microbiological Control

Filtering bacteria and their food supply from the tower water significantly reduces the potential for microbiological growth and helps the biocide program work better.Reduced Maintenance

Unscheduled maintenance and downtime can be extremely costly. Using our controllers ensures that only clean water recirculates, which is not only sound preventive maintenance, but also reduces heat exchanger and tower cleaning costs.

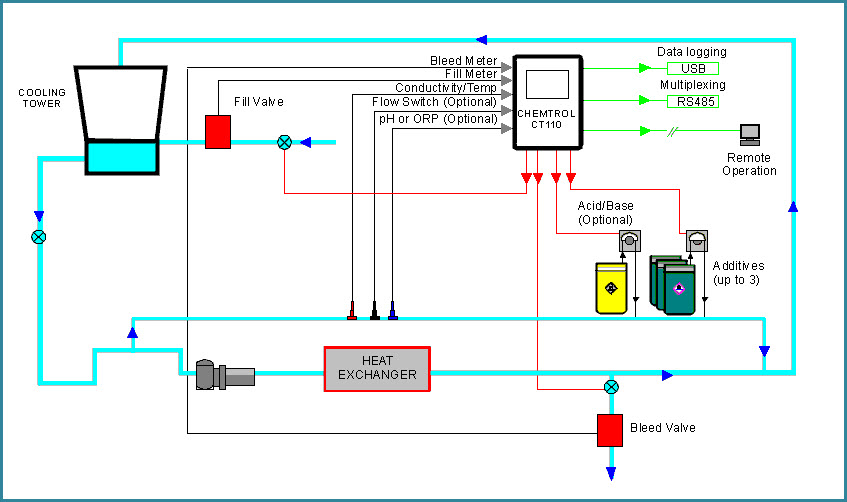

CHEMTROL® CT110 controller diagram installations

CHEMTROL® Cooling Tower Specific Controller

- CHEMTROL® CT110 controller is an easy-to-use but sophisticated programmable controller designed for control of conductivity (Total Dissolved Solids), ORP, pH, and programmable addition of chemical additives – such as inhibitors, biocides, dispersants, etc.

- Its makeup and bleed water-meter input is a standard feature, as is pH control with display of the Langelier Saturation Index (LSI).

- Optional chlorine or bromine level in part per million (ppm) measurement, as well as remote monitoring with our unique web-server communication offers true duplex operation with identical duplicate screens on both the controller and a computer, laptop, mobile App etc.

- Our cooling towers programmable controllers have the ability to be modified based on the type of monitoring and control you require. Customise your setup by adding or reducing components accordingly. That way we can provide a competitive pricing solution based on the functionality you actually need.

Why CHEMTROL® Controllers?

Highlights of our range of integrated controllers include:

- A chemical and energy saving program designed to reduce operating costs

- Web-based access for remote monitoring, full operation and control

- A generous, industry-leading 5-year electronics warranty on the controller

- For industrial facilities automated controllers give peace of mind that all mandatory public health obligations will be met with consistent disinfection under varying conditions

- Our products specifically designed for commercial and industrial applications.

CHEMTROL® and Sustainability

Santa Barbara Control Systems (SBCS), a California-based company is the manufacturer behind our range of Digital, Programmable & Integrated Controllers. With 40+ years of chemical automation, water chemistry research and expertise, CHEMTROL is committed to providing solutions that help make our customers facilities and installations more sustainable. Our unique expertise also positions us to better understand our customers’ sustainability needs and gives us the ability to provide:

- Competitive features and pricing

- Advice on the most suitable product for your application

- Prompt technical support

-

Sustainability: Swimming Pools and Spas

Sustainability and Cost Benefits of CHEMTROL Controllers: Swimming Pools and Spas

With temperatures and energy bills on the rise we all need to come up with smart solutions to mitigate these impacts on the environment, not to mention increasingly stretched budgets.

A major part of devising a sustainable solution should start with identifying what your energy costs are, especially for large public facilities. From here you can look at where savings can be made, set targets and initiate a management plan that improves your facilities overall efficiency and reduces costs.

With this in mind we want to highlight how our range of smart automated water treatment systems can improve efficiency and help you meet a greener (and less costly) standard of operation.

CHEMTROL PC5100 programmable controller reduces UV energy consumption

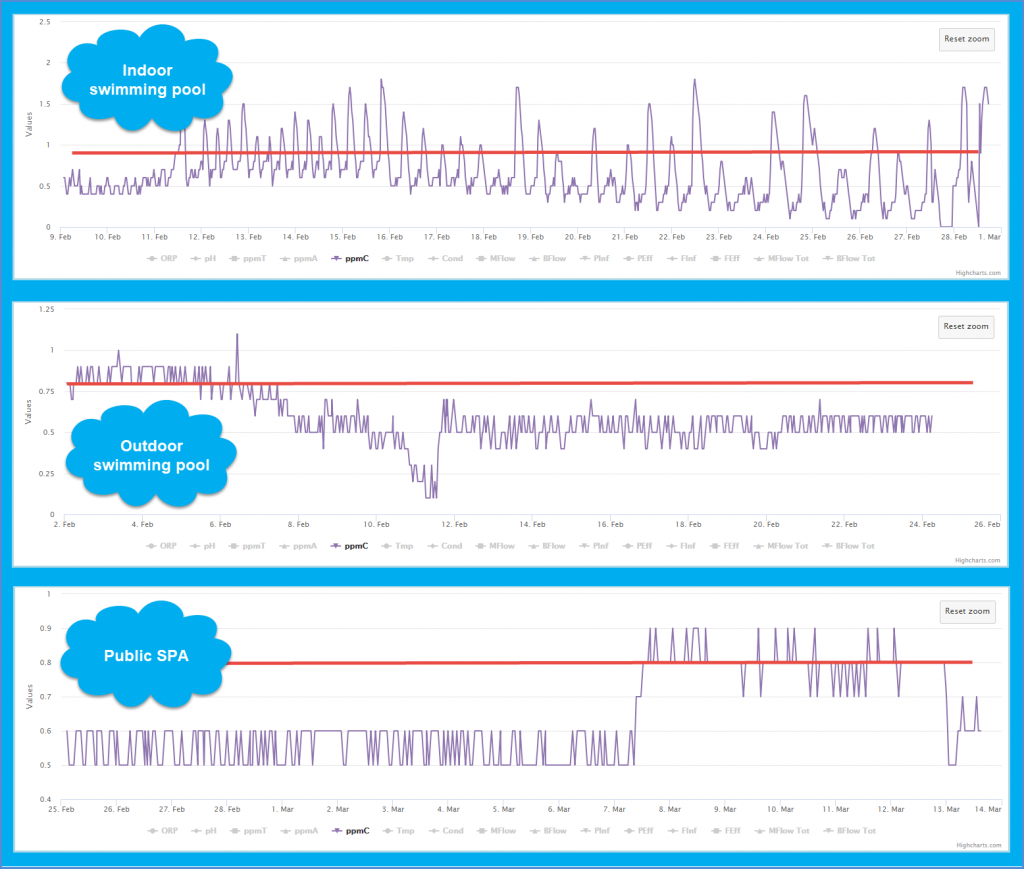

In this example we have identified where our CHEMTROL PC5100 programmable controller can help reduce UV energy consumption, and carbon emissions, using three public swimming pools/spa to illustrate this feature. Ultraviolet systems are popular for their ability to harnesses the power of ultraviolet light to disinfect and sanitize pool water, but they do draw power when they operate.

Our analysis of three public swimming pools & spa over the month of February 19, one indoor (top graph), one outdoor (Middle graph) and the other is a spa (bottom graph), show clearly that the UV systems are operating unnecessarily, and drawing power when they could be in standby mode/off.

The reality is that UV systems only need to operate when Combined Chlorine levels are more than 0.8ppm (above the red line).

In our examples below the outdoor pool and the spa’s UV systems should only be activated a few days per month, while the indoor pool’s UV system should only be operating every day for a few hours. In both cases, there are opportunities to realise significant energy savings given these systems should be turned OFF when measurements are between 0 ppm – 0.8ppm, so there is no need for these systems to work 24/7.

Operators must bear in mind that these three case studies are only used to illustrate the potential of our product. Every facility and pool has its own set of unique circumstances and conditions.

Figure 1: ppmC measurements (1.top graph – indoor public pool, 2. Middle graph – outdoor public pool, 3. Bottom graph – public spa)

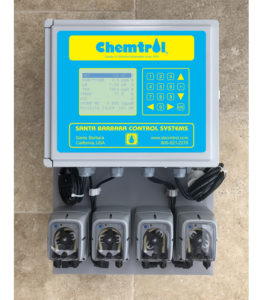

CHEMTROL PC5100 programmable controller

The CHEMTROL PC5100 has a range of unique features, including the ability to measure both Free and Total Chlorine – a unique technology to control dual ppm and measure combined chlorine. It is also incorporates all the monitoring, control and communication functions into a single integrated command center designed around a powerful microprocessor, with an industry-leading 5 year electronics warranty.

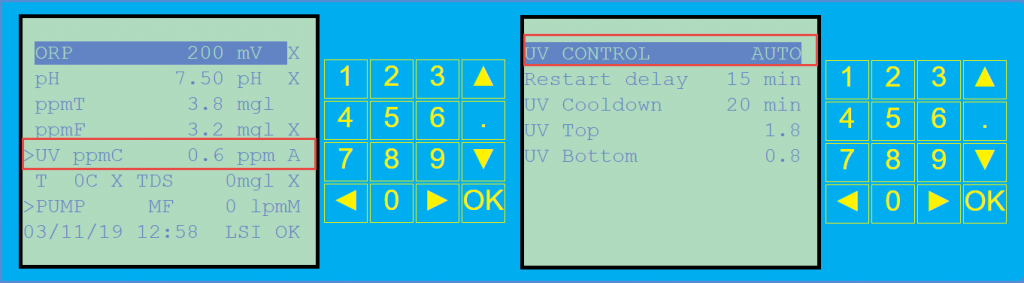

The CHEMTROL PC5100 programmable controller can be connected to your facilities UV system via a dedicated relay to automatically control it based on combined chlorine measurement. The menu on this unit also has a UV cooldown period to protect the UV system in case it needs to be repeatedly turned on and off.

In addition the PC 5100 can connect to UV systems that include 4-20mA electronics, and facilitate automatic control of the UV Sterilization System using a 4-20mA output to ramp up and down the system based on the prevailing chloramine measurement.

Figure 2: CHEMTROL PC5100 programmable controller display screen/menu interface

Why CHEMTROL Controllers?

Highlights of our range of integrated controllers include:

- A chemical and energy saving program designed to reduce operating costs

- Web-based access for remote monitoring, full operation and control

- A generous, industry-leading 5-year electronics warranty on the controller

- For commercial facilities automated controllers give peace of mind that all mandatory public health obligations will be met with consistent disinfection under varying conditions

- Our products are specifically designed and tested for commercial applications including public/municipal swimming pools/spas

CHEMTROL and Sustainability

With 40+ years of chemical automation, water chemistry research and expertise, Santa Barbara Control Systems, with its CHEMTROL controller series, is committed to providing solutions that help make our customers facilities and installations more sustainable. Our unique expertise also positions us to better understand our customers’ sustainability needs and gives us the ability to provide:

- Competitive features and pricing

- Advice on the most suitable product for your application

- Prompt technical support