Latest

-

The Importance of Corrosion Monitoring

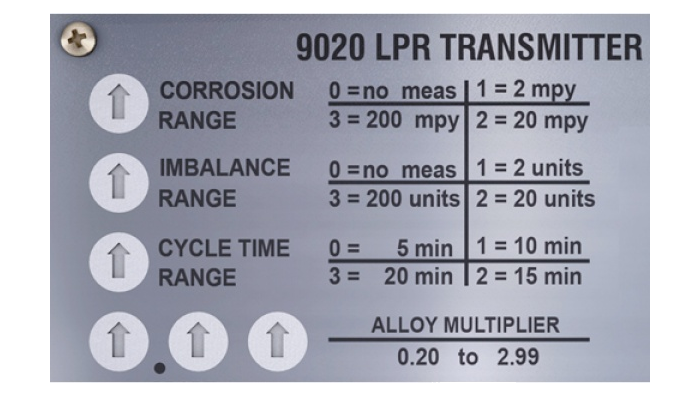

We pair our controllers with several options for corrosion-rate monitoring.

Avoid Costly Maintenance, Downtime and Repairs

If you run an industrial facility, including cooling towers and blast chillers, you will be familiar with the danger that corrosion can cause to your equipment.

In cooling towers and chillers the heat exchange tubes can be severely damaged by corrosion and fouling, which can cause significant loss of efficiency, reduce the life-span of these units and lead to costly maintenance and replacement of these elements.

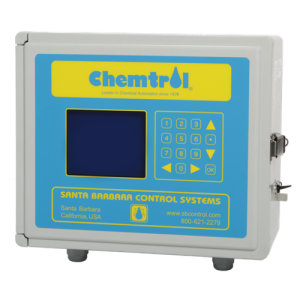

Thankfully we have a corrosion monitoring system – based around the powerful CHEMTROL® industrial grade PC110c controller.

What is corrosion?

Corrosion is when a metal dissolves, typically from a chemical or electrochemical reaction – including low pH conditions (<6.0) and high free chlorine residuals in the local environment. A number of operating parameters can influence the corrosion tendency in an aqueous environment, including conductivity, pH and the concentration of oxygen. Another factor to be aware of is fouling from uncontrolled biological growth, which can also contribute to corrosion over time.

Ultimately corrosion can cause:

Ultimately corrosion can cause:– Reduced plant efficiency

– Equipment failure

– Facility downtime

– The costly replacement of equipmentA less obvious, and more serious type of corrosion is pitting – which occurs on materials such as metals and alloys. It manifests as microscopic corrosive points or pits, where the solution inside the pits become increasingly concentrated and corrosive over time. Galvanic corrosion can also occur in cooling systems that are manufactured from both copper and steel alloys. Microorganisms in cooling water can also cause corrosion, as the by-products they produce – include organic acids and hydrogen sulfides – which are corrosive to metals.

The benefits of corrosion monitoring

If you want to protect your investment and reduce the life-cycle costs associated with your operation some form of corrosion monitoring can help provide:

If you want to protect your investment and reduce the life-cycle costs associated with your operation some form of corrosion monitoring can help provide: - An early warning system to alert you to damaging conditions before a corrosion-induced failure can occur.

- Insights on the parameters that have impacted your system, including the pressure, temperature, pH or flow rate.

- Evaluation of the effectiveness of corrosion prevention measures, such as chemical inhibition.

- Data to inform ongoing management measures and maintenance requirements of your facility.

The CHEMTROL® PC110c controller provides measurements of Conductivity/TDS, pH, Chlorine/Bromine (ppm), ORP and temperature, as well as corrosion and liquid level monitoring. These features can help ensure:

- Sanitizer control of biocide additions

- A low enough pH is maintained to eliminate scale formation

- Timed chemical treatment to help prevent biological fouling

- Timed biocide additions with “shock” cycles at regular intervals

We pair our controllers with several options for corrosion-rate monitoring

-

CHEMTROL® Controllers Are 5G Compatible

5G Compatible

We are pleased to announce that our range of controllers are compatible with 5G, the next generation mobile technology currently being rolled out.

5G offers more capacity, superior reliability and faster connections for any connected devices.

This is in addition to the other connectivity options available including utilising a wired connection (Ethernet), WiFi (including multiple controllers sharing a single connection) and 4G LTE.

This is in addition to the other connectivity options available including utilising a wired connection (Ethernet), WiFi (including multiple controllers sharing a single connection) and 4G LTE. Our controllers range can also be configured to communicate with facility Building Management Systems, using open protocol languages such as Modbus IP, Modbus RTU, BACnet IP, BACnet MSTP and LonWorks.

What is 5G?

5G wireless technology is the next generation wireless network which offers high speeds, faster downloads, superior reliability and ultra low latency. It is significantly faster than 4G, has more capacity and uses the wireless spectrum better than 4G.

5G wireless technology is the next generation wireless network which offers high speeds, faster downloads, superior reliability and ultra low latency. It is significantly faster than 4G, has more capacity and uses the wireless spectrum better than 4G. To take advantage of 5G you need compatible devices, as well as a plan that includes access to the 5G network, which is rolling out in selected areas.

5G: Integrated with Chemtrol

Our range of controllers come integrated and ready to go with the 5G router, which sits inside the controller cabinet. This is a seamless and robust solution, as all components are installed in one box, and it operates the same way as our 4G network solution.

Our range of controllers come integrated and ready to go with the 5G router, which sits inside the controller cabinet. This is a seamless and robust solution, as all components are installed in one box, and it operates the same way as our 4G network solution.You can also use the controller as a stand alone unit or in a shared setup where multiple controllers are connected via one router using WiFi.

-

Total Cost of Ownership (TCO)

Understanding total cost of ownership (TCO) when purchasing Chemtrol controllers

Are you planning on making an investment in your facilities water treatment, chemical automation or water chemistry capabilities?

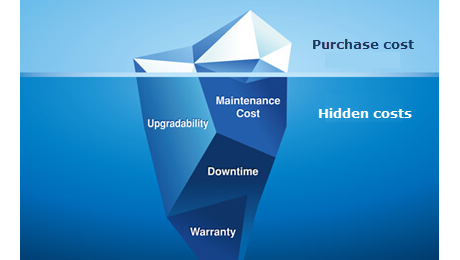

Then you need to research the total cost of ownership (TCO) of an item before you spend a cent of your budget.

Let’s first define TCO before we detail why this is crucial – and what you need to consider when making an investment in any asset or equipment.

What is the total cost of ownership (TCO) and why does it matter?

TCO is a way of looking at the long term value of an item to your business, taking into account the:

– Initial purchase price

– Operating costs over its lifespan

– Maintenance costs over its lifespan

– Environmental impact of the item over time

The TCO ultimately impacts the ROI of an item to your business, and is a way of assessing the long-term value of a purchase to your business or operation. It is an important factor to take into account as operating and maintenance costs aren’t always reflected in the upfront pricing of an item.

Now let’s take a look at how TCO is relevant to our line of products.

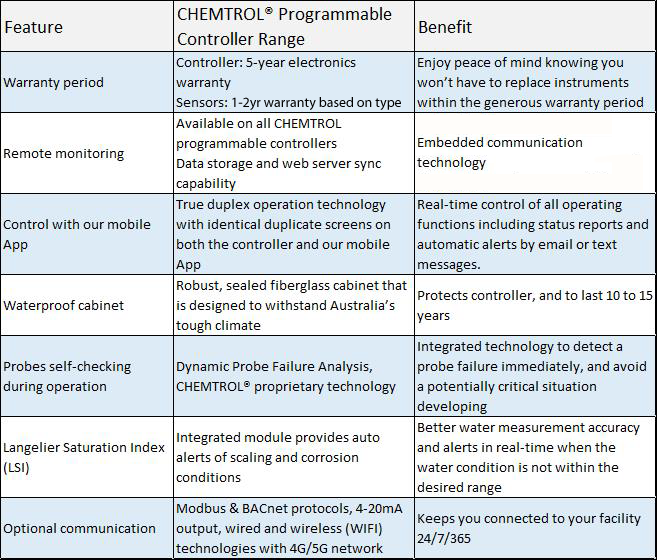

Total cost of ownership (TCO) – Chemtrol vs. competitors

As a manufacturer with 40+ years of research and development in the field of chemical automation and water chemistry, our expertise has allowed us to produce equipment with industry leading precision, reliability and features.

This is reflected in the price point of our range of programmable controllers for industrial and commercial applications – something we are not ashamed to admit or discuss. It is however a factor which can be an obstacle for some who fail to take into account the TCO of an item.

This is reflected in the price point of our range of programmable controllers for industrial and commercial applications – something we are not ashamed to admit or discuss. It is however a factor which can be an obstacle for some who fail to take into account the TCO of an item. Our table below sets out the case for avoiding the ‘buy cheap, buy twice’ approach, which is false economy over the medium/long term.

Get in touch for advice on the best programmable controller for your facility, that way we can provide a competitive pricing solution based on the functionality you need.